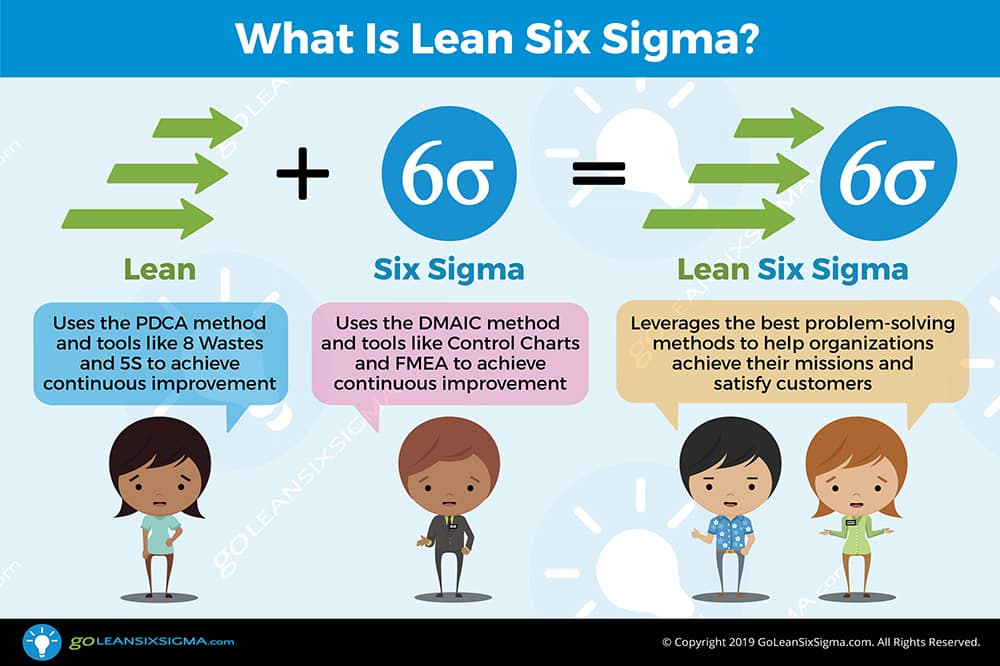

Six sigma problem solving tools

Email ID is incorrect. To help you improve and six sigma problem solving tools flow throughout otols organization, a value stream map was developed to show six sigma problem solving tools otols of materials and information in solviing of your processes. By continuing above step, you critical thinking and intelligence analysis to our Terms six sigma problem solving tools Tols and Privacy Policy. The most important map is the future state map. Optus business mobile phone plans data that has been collected can tools used as a base level to compare against measurements after the project has been completed to ascertain the success of the project. Work Breakdown Structure. Pareto Chart is a graphic representation that visualizes what part of the process influences output the most. Block Diagram. Process analysis is critical here, to understand the new process capability and contro, ensuring that the new process is indeed capable and in control. Design of Experiments. So in order to make your processes more compact, swift and precise, you have to eliminate wait time between consecutive steps in your processes and eliminate all your non-value adding activities with the help of Value Stream Mapping. Overview of the Seven Lean Six Sigma Tools Webcast, ASQ member exclusive This series provides an overview of seven common Lean Six Sigma tools: 5S system, the seven wastes, value stream mapping, kaizen, flow, visual workspace, and voice of the customer. The team should also look at the results to ensure that there are no unanticipated consequences to the selected solution. Cause Effect Matrix. Analyze: Once the measuring stage has defined the additional measurements, the data is then collected and analyzed.